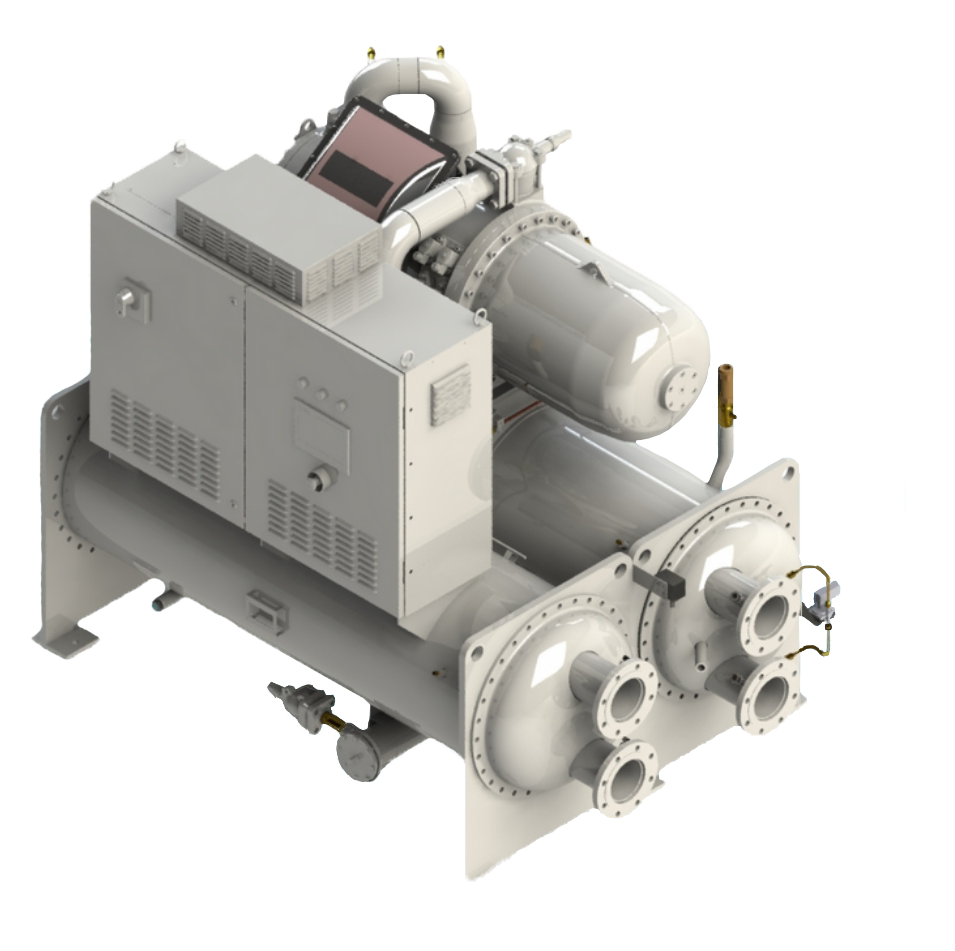

High-Temperature Water-Cooled Screw Chiller

100–300 RT • Cooling & Heating • Hot Water up to 185°F

EXINDA’s next-generation high-temperature water-cooled screw chillers deliver both cooling and high-temperature heating in a single VFD-driven platform. With hot-water outlet temperatures up to 185°F (85°C) and cooling capacities between 100–300 tons, these units are engineered for applications where conventional chillers cannot meet performance or temperature requirements.

Powered by an efficient screw compressor with real-time compression-ratio optimization, the system provides fast loading, quiet operation, and exceptional part-load efficiency, making it ideal for comfort cooling, process loads, and mission-critical facilities.

EXINDA High-Temperature Water-Cooled Screw Chiller

The EXINDA high-temperature water-cooled screw chiller is designed to deliver reliable cooling and high-temperature heating for industrial, commercial, and mission-critical applications. With a wide capacity range (100–300 tons) and hot-water production up to 185°F (85°C), this system supports air-conditioning, hydronic heating, domestic hot water, and process loads in a single integrated platform.

The fully VFD-driven screw compressor continuously optimizes compression ratios, ensuring excellent efficiency across all load conditions. The chiller maintains quiet, adaptive performance and includes fast-loading capability, allowing cooling or heating recovery within seconds after a power interruption.

Using R515B, a low-GWP next-generation refrigerant, EXINDA supports higher efficiency and sustainability targets while reducing environmental impact compared to traditional refrigerants.

01 — Dual-Mode Operation (Heating + Cooling)

Provides chilled-water cooling and high-temperature heating up to 185°F (85°C) in a single unit.

02 — High-Efficiency Screw Compressor

Real-time compression-ratio optimization enhances performance in all seasons and part-load conditions.

03 — Fast-Loading Capability

Cooling or heating recovers within seconds after a power outage — essential for mission-critical facilities.

04 — Quiet, Adaptive Operation

Low vibration and noise levels, ideal for comfort cooling and process-cooling environments.

05 — Water-Cooled Heat Exchangers

Shell-and-tube condenser and flooded evaporator deliver stable and efficient heat transfer.

06 — Advanced VFD-Driven Platform

Fully variable-frequency compressor start with 50%–100% stepless capacity control.

07 — R515B Low-GWP Refrigerant

Supports sustainable building strategies with reduced environmental impact.

08 — Siemens PLC Control System

7-inch LCD touchscreen with water-temperature PID control and full protection suite.

09 — Comprehensive Safety System

Includes high/low-pressure protection, over-current/over-temperature protection, freeze protection, and safety valve.

10 — Ideal for Complex Commercial Applications

Comfort cooling, domestic hot water, hydronic heating, process loads, and critical facilities.

Technical Performance

Performance — AHRI Conditions

● Cooling Capacity: 95.8 RT (337 kW)

● COP: 4.96

● IPLV.IP: 7.14

Heating Performance — AHRI Conditions

● Heating Capacity: 140.2 RT (493 kW)

● COP: 4.46

● Hot Water Outlet Temp: 140°F

Heating Performance — High Temperature

● Heating Capacity: 124.7 RT (438.4 kW)

● COP: 2.70

● Hot Water Outlet: 176°F

Electrical

● Power Supply: 3-phase, 440–480V, 60 Hz

● Rated Power: 68 kW

● Rated Current: 124 A

● Max Operating Current: 290 A

Compressor

● Type: Screw

● Quantity: 1

● Starting: Variable-frequency start

● Capacity Control: 50%–100% stepless

Condenser (Water-cooled, shell-and-tube)

● Inlet Water Temp: 85°F

● Outlet Water Temp: 94°F

● Chilled Water Flow: 52.1 m³/h

Evaporator (Flooded shell-and-tube)

● Inlet Water Temp: 54°F

● Outlet Water Temp: 44°F

● Cooling Water Flow: 68.4 m³/h

Refrigerant System

● Refrigerant Type: R515B

● Charge: 125 kg

● Expansion: Electronic expansion valve

● Circuits: 1